Grease Separators EN1825

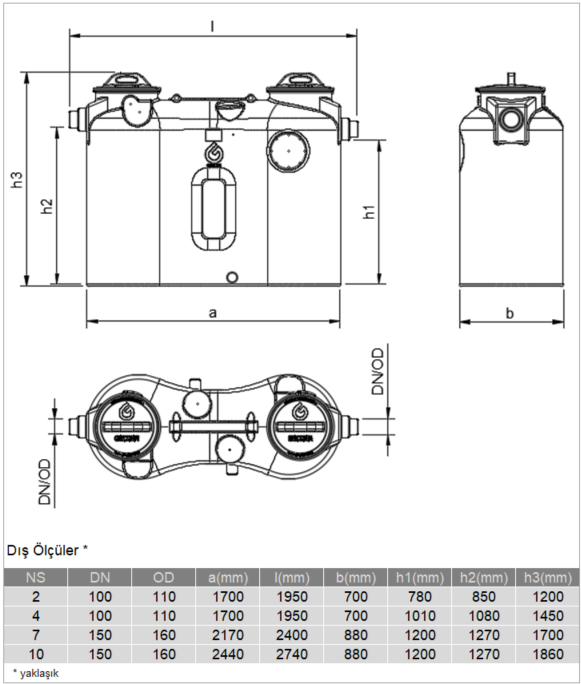

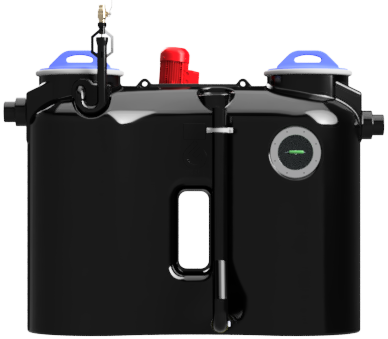

Products designed for wastewater systems are manufactured from polyethylene (HDPE) material by rotation method in accordance with EN 1825-1 and are TSE certified. It has a structure that is suitable for above-ground installation and retains floating and settling materials. If desired, it can be connected to vidanjor suction with DN 65/d75 flange or Storz B 75 coupling without opening the cover for odorless discharge.

Oil Separators have a smooth surface that is resistant to oil and acids on the inside and outside, and does not contain residue on the inside. Optionally, there is an oil level meter alarm device and a sampling shaft after the product.

Advantages

- Solid body made of polyethylene (PEHD)

- Easy and economical to assemble

- Easy maintenance, corrosion resistant

- 100% odor-proof

- Extremely long life, lightweight

- Environmentalist

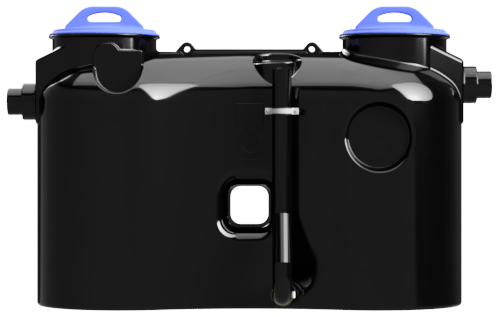

The BASIC model, with its leak-proof covers, is suitable for use in areas where bad odors do not cause discomfort during maintenance. The access cover will be opened for the disposal (removal) of accumulated oil and solids with a sewage truck.

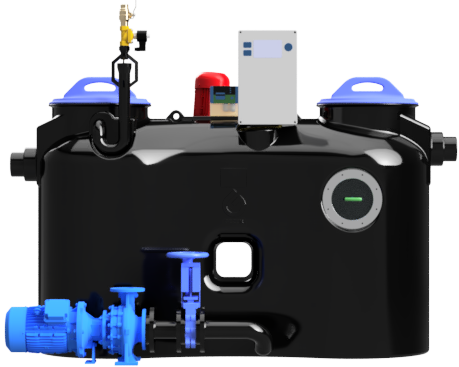

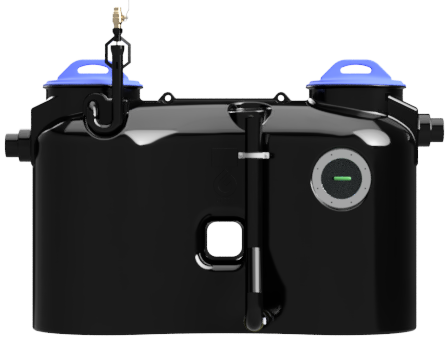

The ADVANCED model provides odorless operation without the need to open the cover. The accumulated oil layer can be seen through the observation window. After reaching the maximum oil level, accumulated contaminants are eliminated through a suction pipe with a vacuum cleaner. After it is completely disposed of, clean water is filled into the oil separator by opening the manual ball valve.

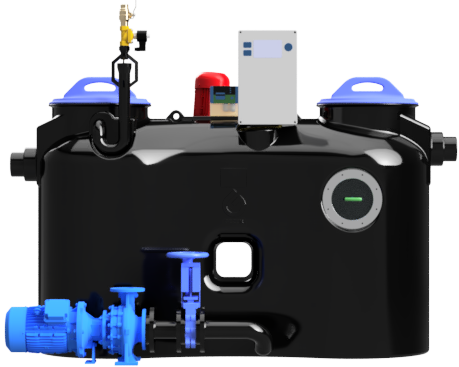

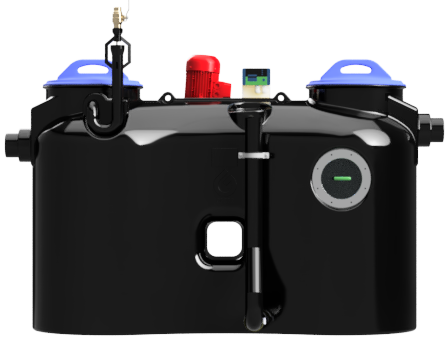

The MIX model is equipped with an oil level alarm that indicates when the maximum level of accumulated oil has been reached. Before discharging, the mixer is operated to mix the oil, water and solid layers, facilitating the elimination of contaminants in the grease separator tank. The suction pipe is available for discharge by the sewage truck. After complete disposal, clean water is filled into the oil separator unit by opening the manual ball valve.

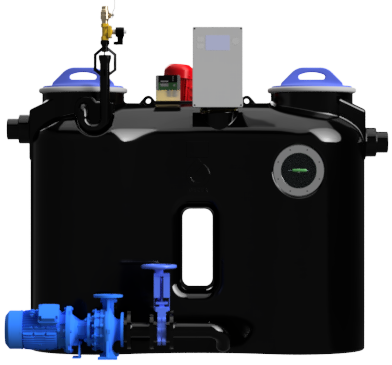

The AUTO model is the product that includes a discharge pump and is equipped with a program-controlled discharge system. When the maximum level of accumulated grease is reached, the grease alarm initiates automatic drain mode. First of all, the mixer is started to mix the oil, water and solid layers. The discharge pump is then started to discharge the grease separator. After the grease separator is completely emptied, the inside of the separator is rinsed with the discharge pump using clean water filled through the filling unit. After rinsing, the grease separator is completely filled with clean water.